Mincovňa Kremnica, founded in 1328 by King Charles Robert of Anjou, is one of the oldest continuously operating mints in the world. Currently a state enterprise, it has undergone many changes since its inception, all while maintaining a high standard of quality and innovation.

In addition to circulating coins and medals, the mint produces a wide range of products such as plaques, badges, pendants and a variety of awards, as well as commemorative and collector coins made from precious metals.

Today, it is known for its high quality and innovative technologies, which is confirmed by two important ISO certifications. One was awarded for an excellent quality management and the other for effective environmental management.

Modernization over the centuries

The mint has a long history of technological progress in coin minting. Over the centuries, the factory has undergone several innovations and modernizations. In the 18th century, the switch was made from manual to machine minting, galvanoplasty was later introduced and the minting process was perfected by introducing new machines and techniques.

Significant modernization also took place in the 20th century, when electric stamping machines and process automation was introduced. These technological advances have made it possible to increase the quality and efficiency of production, which has enabled the mint in Kremnica to maintain a high standard and competitive advantage.

In addition to new procedures and techniques in coin minting, the mint is also introducing modern energy technologies supporting its environmental goals. In an effort to improve energy efficiency and reduce its carbon footprint, which is now an integral part of responsible business methods, Mincovňa Kremnica decided to install a modern smart battery storage brAIn by FUERGY.

The first stage of installation

The installation at the Mincovňa Kremnica was carried out in two phases. Based on an energy analysis of the operation, in which we look at the diagram of electricity consumption, reserved capacity and maximum reserved capacity, and considering the annual electricity consumption of approximately 1200 MWh, we designed a battery storage with a capacity of 216 kWh and an output of 200 kW.

After inspecting the installation site, the substation, which is located right next to the switchboards, proved to be a suitable location for the battery storage. We filled the storage with LiFePO₄ batteries from Pylontech, which have a lifespan of 15 years. These batteries meet the strictest safety and fire standards, guaranteeing the reliability and safety of the entire system.

In the first phase, the storage operated in a limited mode, which only took into account the energy demand itself. In other words, the storage was charged at times when demand was low and the price of electricity was lower, releasing energy for the mint's consumption during peak times when demand was high and the price of electricity was higher.

Other factors did not yet enter into the management of the repository, such as planned and current electricity consumption, predictions of electricity consumption development, the situation in the transmission system, or other data necessary for more sophisticated storage management, which brings much more interesting financial results. This followed in the second phase.

The second phase of installation

After installation of the battery storage, the mint decided that it would like to use part of the battery storage capacity intended for the regulation of deviation as a backup power source for the backup of some technologies in the building.

In the second phase, we expanded the battery system with a 50 kW UPS inverter to provide the functionality of a UPS backup power source for production facilities, server room and the boiler in the boiler room as well.

After changing their energy supplier, the storage facility could also begin to fulfill its primary role – to regulate the consumption of electricity at the delivery point in order to generate a financial profit from the provision of non-certified ancillary services. This reduces the overall energy costs and carbon footprint of the delivery point.

Since the launch of the battery storage in full FUERGY mode, the company has already saved 8 tons of CO2e emissions, which is a reduction of 12.46% compared to the period when they did not have battery storage.

The project was fully financed by the customer Mincovňa Kremnica. In order for the the storage to be utilized to its fullest, a switch was made to the electricity supplier Slovenské elektrárne – energetické služby.

The mint has also installed solar panels with an output of 17 kilowatt peak (kWp). They are managed at their own expense.

Maintenance and service

Our work did not end with the installation of battery storage and its commissioning. We monitor the entire system online 24/7, down to the level of individual battery cells and individual components. At the same time, we provide online fault diagnostics and regular service of the entire device.

FUERGY, as the only full-service energy technology company in Slovakia, provides the entire process of battery storage implementation, from energy analysis through installation to service and maintenance.

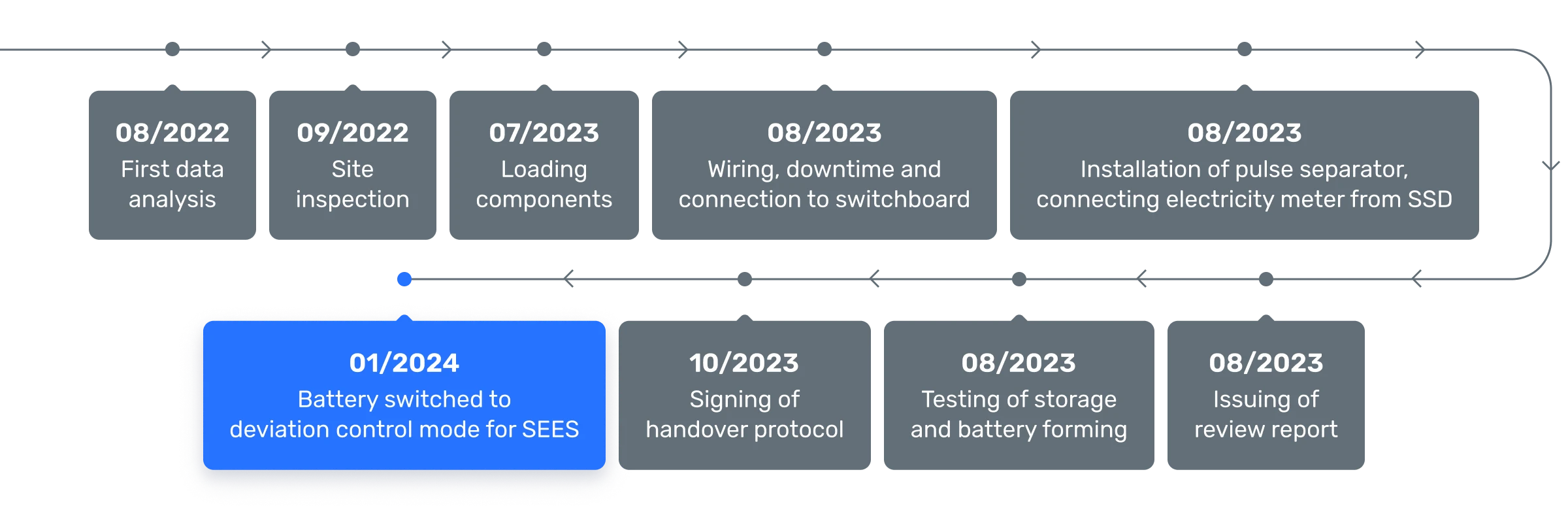

Schedule

Are you interested in a project like this? Then do not hesitate to contact us. We will be happy to prepare a tailor-made solution for you, with which you will save not only your costs, but also emissions.

New dimension of energy optimization