Founded in 2001, Amico Drevo s.r.o., continues a long tradition of woodworking in the Orava region. Located beneath the majestic Orava Castle, the factory spans nearly 15 hectares, processing wood from nearby forests, with production focused on processing spruce and producing construction joinery products, unfinished wood products and biofuel pellets.

The company's headquarters in Oravský Podzámok is situated in an area rich in woodworking history, dating back to Juraj Thurzo, owner of the Orava estate. His descendants established the Orava Forest District, managing forests covering over 200,000 hectares. In the 18th century, timber harvesting and sales became the main sources of income for the district, leading to the development of forestry and the construction of several sawmills in the region.

Today, Amico Drevo delivers high-quality products used not only in construction, but also in the production of interior furniture.

Emphasis on Ecology and Modern Technology

The company emphasizes ecological principles, as evidenced by certifications ensuring that the wood comes from sustainably managed forests. Additionally, they continually invest in modern technologies to ensure high product quality and innovations in production.

The latest addition to their portfolio is the smart battery storage brAIn by FUERGY, installed in collaboration with the energy supplier Slovenské elektrárne – energetické služby s.r.o. (SEES). This step brings the company closer to energy efficiency and sustainability. Rather than purchasing the storage directly, Amico Drevo is leasing it from their energy supplier.

Battery Storage Installation

The installation of the battery storage was preceded by an energy analysis, which reviewed the factory’s electricity consumption diagram, including reserved capacity and maximum reserved capacity. This analysis provided a comprehensive view of the energy needs and optimization possibilities for operations.

With an annual electricity consumption of approximately 6,400 MWh, we designed an external battery storage system with a total output of 800 kW and a capacity of 864 kWh, divided into two separate container systems. This design was carefully chosen to meet the specific needs and goals of the company.

The properly selected output and capacity of the storage ensures that it is not only technically efficient, but also economically advantageous for long-term use, optimizing energy costs and contributing to reducing Amico Drevo's carbon footprint.

Site Inspection

After inspecting the installation site, an area near the transformer station was found to be the most suitable location for the battery storage, offering optimal access for connection to the energy infrastructure and sufficient space for safe and efficient installation of the storage.

However, the original panel surface was not stable enough to support heavy construction, so it was reinforced with a concrete base. This adjustment ensured that the installation would be stable and durable.

Battery Storage Safety

The storage was filled with LiFePO₄ batteries from Pylontech, which meet the highest safety and fire protection standards, ensuring the reliability and safety of the entire system.

Each battery storage container was equipped with a modern safety and monitoring system, ensuring a high level of protection and control. The equipment includes a sophisticated camera system providing continuous surveillance of the entire storage area.

This system not only monitors movement in the container space, but also tracks the internal condition and activity within the containers. This technology allows real-time monitoring of potential risks or unusual system behavior, increasing the overall safety and reliability of the storage operation. This approach enables a rapid response to any incidents and ensures that the battery storage operates efficiently and without interruption.

The storage is also equipped with two built-in cooling units, essential for maintaining optimal operating temperatures of the batteries, preventing overheating and ensuring the long-term reliability of the system.

Fire Protection System

Installing a fire protection system in the battery storage is not mandatory as current legislation does not impose such a requirement on owners. However, for safety reasons, we recommend equipping any battery storage with an appropriate fire extinguishing system. SEES is fully aware of the potential risks associated with operating battery systems and therefore willingly invests in this measure.

The battery storage at Amico Drevo was equipped with a professional aerosol fire extinguishing system, designed to react quickly and effectively to any potential fire, thereby enhancing overall safety and minimizing damage risks.

Task of the Battery Storage

The task of the smart brAIn battery storage at Amico Drevo is to regulate electricity consumption at the delivery point in order to generate financial profit from the provision of non-certified ancillary services and additionally reducing overall energy costs and carbon footprint.

The storage adapts not only to the needs of the consumption site, but also to the entire electrical grid. In short, the storage charges when there is a surplus of electricity in the grid and discharges into the consumption site when there is a shortage.

The storage earns financial profit for assisting the grid, from which Amico Drevo receives a share in the form of a fixed annual bonus from their energy supplier. The storage thus does not reduce the consumption site’s electricity usage or the price of electricity, but generates extra income for Amico Drevo, helping to optimize their energy costs.

Solar Energy Optimization

The factory also has solar panels with an installed capacity of 490 kW. The task of the brAIn storage is to ensure that the company utilizes as much locally generated solar energy as possible.

During the process, we encountered a technical challenge requiring our expertise. Since we could not communicate directly with the photovoltaic inverter via software, we developed and implemented a special device to measure the amount of generated solar energy. This allows us to manage the energy effectively. When the solar panel system generates more energy than needed at the time, we can store it in the battery storage.

By storing excess energy in the battery storage instead of sending it to the grid, the company minimizes the risk of having to pay for sending surpluses to the grid when electricity prices are negative. This approach not only protects the company from potential losses, but also increases overall energy management efficiency and contributes to better use of its energy resources. The section of the storage capacity that is not currently storing solar surpluses is then used to earn from assisting the grid, maximizing its capacity utilization.

In this way, Amico Drevo improves its energy self-sufficiency while supporting a sustainable and economically advantageous model for green energy production.

Transformer Replacement

For the successful implementation of the entire energy system, it was necessary to replace the transformer, which was upgraded from an older 1000 kVA model to a new one with a capacity of 1600 kVA. The replacement was handled by the energy supplier SEES.

This upgrade was a key requirement for ensuring the smooth operation of the entire system and its full performance. Thanks to this modernization, it is now possible to optimize energy flow, significantly contributing to the overall stability and efficiency of operations.

The project was financed by SEES under the Energy as a Service model, which allows the customer to benefit from all advantages without the need for their own investment costs or administrative burdens.

FUERGY, as the only full-service energy technology company in Slovakia, provides the entire process of battery storage implementation, from energy analysis through installation to service and maintenance.

Given that the smart brAIn battery storage effectively replaces primarily fossil sources in providing non-certified ancillary services, maintaining grid stability, it also effectively lowers emissions. Since the full FUERGY operation of the battery storage commenced, the company has reduced CO2e emissions by 28 tons, representing a 11.72 % decrease compared to pre-storage data. The emissions saved can also be reported by Amico Drevo in their ESG report.

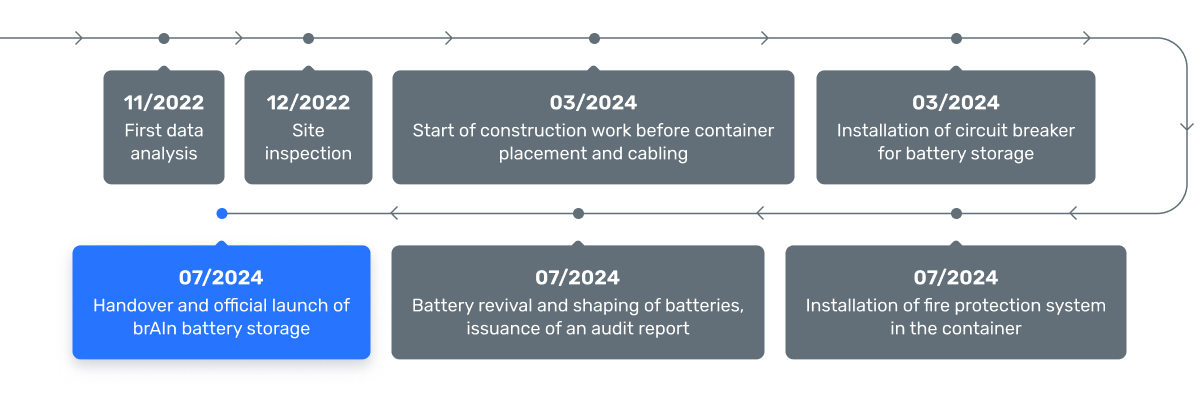

Schedule

Are you interested in a similar project? Then do not hesitate to contact us. We will be happy to prepare a tailor-made solution for you, which will save not only your costs, but also emissions. Also, check out our other completed projects.

New dimension of energy optimization